With SPAI the installation and validation of the machines do not stop

The actual COVID-19 (Coronavirus) pandemic will have a huge impact on the way we live, work and on the world economy. It is expected that we will rethink globalisation model of the production of goods that seemed to be acquired and unstoppable. We will see, perhaps, a reverse phenomenon to delocalization, with some production chains returning within national borders and, at the same time, the mobility of technicians between different nations will decrease. Goods and machines will travel, people will do it much less. Many companies, in these weeks, are becoming familiar with smart working systems, video conferencing and remote assistance. Many things are changing quickly.

Remote installation and validation

How many machines, in these weeks, have arrived at their destination and are waiting for parent company’s technician to install them and put them into production? When will that technician be able to go to that country to complete the work?

Let’s take a concrete example: your company had designed, built and sent a machine to a customer in China (or anywhere else in the world). The machine had arrived at its destination and your technician was about to leave to reach the destination and finish the installation. Just at that moment the pandemic broke out, now the machine is stopped and unproductive and you do not know when and how you can send a technician to finish the job. These factors can also slow down billing and takings.

There are a lot of similar situations right now. Machines to install, to repair, to validate. When and how can we start travelling again? With what costs and times (quarantine to enter and leave the countries, drop in flights and airlines).

What SPAI can do for you

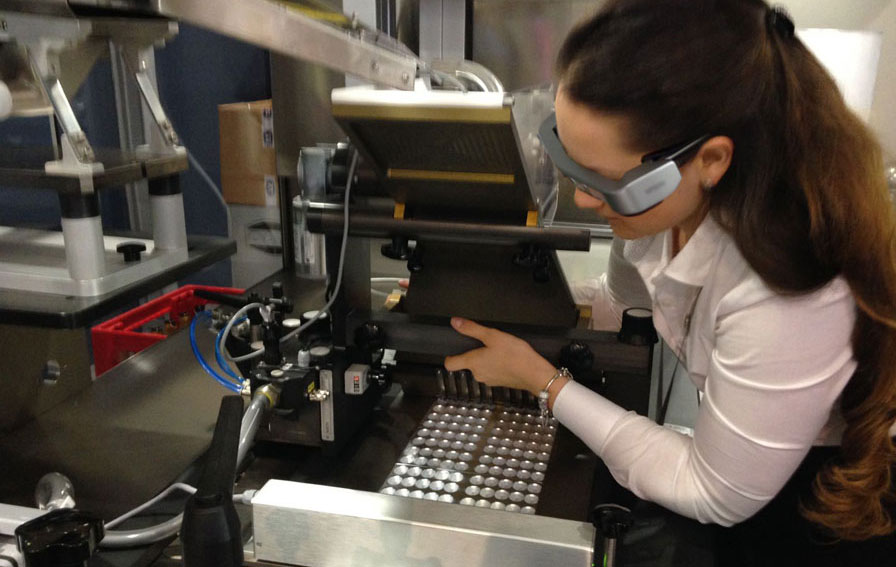

At Spai we can follow installations, repairing and validation of automatic machines all over the world through a remote assistance system using smart glasses and, above all, thanks to a team of technicians native speakers in English, French, Arabic, German, Polish and other languages. Try to think about the difference between sending a technician on site and having to guide a third person through remote instructions. The support technician works directly on the machine, which he knows perfectly, without the need for special language skills and clarity in the presentation of the contents, because he or she works on the machine himself/herself. It is very different, instead, to have to drive a third person, who does not know the car, through instructions given from a distance. Language and clarity of content are essential.

We can connect the end customers with the technicians who were supposed to carry out the activity, we provide technical support for the software, a technician who will act as a control and translation between our customer and the end customer. Our service consists of the following steps:

- Check the availability of an end customer wireless data network and the necessary requirements at the installation location.

- Supply or assistance in the purchase of Smart Glasses.

- Technical support for the software use and the translation of the instructions to be given for the installation and/or validation of the machine.

Thanks to us you can give continuity to your business and look forward to the future of your company, even now.

The Help4Tech service

“We started with the Help4Tech service more than a year ago – continues Farneti – when nobody would have thought what happened afterwards”.

Help4Tech is an outsourced service offered to automatic machine manufacturers who, with the help of Spai technicians, will be able to assist the end customers through a remote and professional technical assistance. The manufacturer will be involved only in case of real need, but he will be able to count on an accurate triage that will allow him a precise and resolutive diagnosis, avoiding in this way problems deriving from communication defects, including empty trips or the sending of incorrect spare parts.

In practice, the user who wants this service opens a service contract with his supplier who opens it with us at Spai. It could be a service for rent or a plus that the manufacturer sells by adding it to the price of the machine. Spai will only have to invest in training, but if the customer has also entrusted us with the production of the use and maintenance manual for that particular machine, he will not pay for the training because it is already included in that task. In this case the training time is actually reinvested in this new service, which is also convenient from the point of view of the after-sales contact with the final customer. We provide the manufacturer of automatic machines with a help-desk that takes care of a first selection. The on-site technician calls and we respond with a precise order from his customer. If necessary we put ourselves in bridge mode with the manufacturer and work to find a solution. If it is not possible to solve the problem remotely, you can think about sending a technician sent by the customer, but in that case he will arrive on site having very clear the problems that emerged during the first phase.